MEA Preparation

Fuel cell performance of the catalyst is evaluated by actually conducting power generation tests. We incorporate the membrane electrode assembly (MEA), which consists of the catalyst layers, the polymer electrolyte membrane, and the gas diffusion layers, into the test cell in power generation tests. Therefore, each process is required to produce MEA from catalyst powder. At FC-Cubic, we have a consistent system from preparation of catalyst ink to it of MEA.

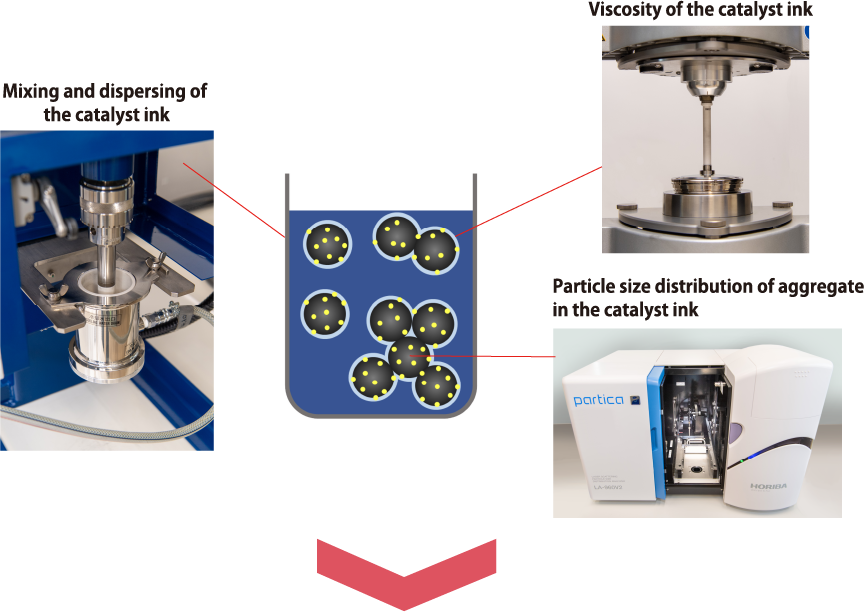

Catalyst Ink Preparation

The catalyst ink is prepared by uniformly mixing the fuel cell catalyst, ionomer and solvent. The viscosity of the ink and the aggregation of the catalyst are controlled to minimize the impact on the power generation performance.

Ink Coating Process

The catalyst ink is applied to the sheet with a uniform thickness using a blade-type or a spray-type coating device. In the spray coating process, the catalyst layer can be directly applied to the polymer electrolyte membrane. The surface morphology of the catalyst layer after coating is observed with a microscope to check for thickness, cracks and so on.

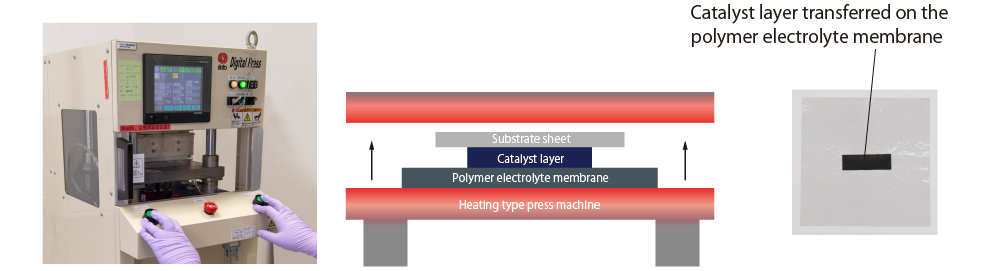

Transfer Process

In transfer process, the catalyst layer coated on the sheet is transferred to the polymer electrolyte membrane. The catalyst layers of anode and cathode are transferred to the polymer electrolyte membrane, respectively. Furthermore, the MEA is finally completed by laminating the subgasket and gas diffusion layer (GDL) by thermocompression bonding.